PadPak

The environmentally friendly paper cushion system

Cushioning, fixing and protecting medium-weight and heavy packaged goods is very easy with the PadPak system. For the different requirements of the packages, four different systems are available. There are no high costs for individually adapted packaging, as PadPak protects the products universally. A further advantage of the PadPak system: While many materials only cushion the packaged goods, PadPak also cover the existing cavities.

Can be easily integrated into existing packaging environments

Paper padding at the push of a button

Paper cushions can be issued automatically

Consumables on a roll and as a package

To cushion environmentally with paper

PadPak is a modern packaging system, based on paper. It describes a very stable protective cushioning that is particularly suitable for medium and heavy packaged goods. Thanks to its volume, it also fixes the product firmly in the outer cardboard box. Besides cushioning, protecting and fixing packaged goods, PadPak also covers existing cavities in the outer box.

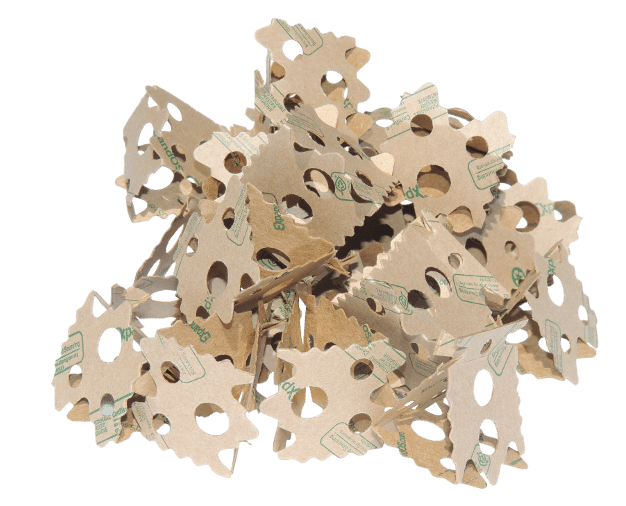

The smooth paper is processed inside the machine, by crumpling it. By using this technique, in the interstices of the cushion pads arises air. The air provides for the volume and further causes a protective cushioning effect, as it absorbs shocks and vibrations. This crumpling technique is combined with a gearwheel technology. The paper is fixed and ensure, that the cushion remains closed and therefore gives enough stability. The protective effect of PadPak is therefore permanently guaranteed.

PadPak is supplied in the form of one or more lays of craft paper. A so-called converter then crumbles the paper cushions from this material. Belonging to the need, different converters and types of paper are available.

For every need the right PadPak sysem.

| PadPak Junior | PadPak CC | PadPak LC | PadPak Senior | PadPak Guardian | |

|---|---|---|---|---|---|

| converter |  |  |  |  |  |

| Dimensions (horizontal) | 80 x 78 x 154 cm | 51 x 81 x 55 cm | 83 x 110 x 166 cm | 94 x 176 x 163 cm | 61 x 110 x 163 cm |

| Dimensions (vertical) | - | - | 83 x 76 x 188 cm | 94 x 100 x 225 cm | |

| Weight | 47 kg | 50 kg | 100 kg | 175 kg | 93 kg |

| Operation | Hebel | Manuell EDS Automatik | Fußschalter EDS Automatik | Manuell Fußschalter Automatik EDS | |

| paper | |||||

| Quality | 70/70 g/m² | 70 g/m² 50/50 g/m² 50/70 g/m² | 70 g/m² 90 g/m² | 50/50 g/m² 50/70 g/m² 70/70 g/m² 50/50/50 g/m² 50/70/50 g/m² | 70/70 g/m² 70/75 g/m² 90 g/m² |

| length | 160 m | 360 m 215 m 180 m | 360 m 300 m | 400 m 335 m 290 m 270 m 235 m | 300 m 180 m |

| More information | |||||

| data sheet |

PadPak Senior: This converter is particularly suitable for medium to large requirements for cushioning material. Using an electronic control panel , an automated production of upholstery material can take place. A practical foot pedal helps you that the work can be done in a manual mode. Particularly for the large and heavy products, for this converter also a PadPak Coiler is available, which automatically winds the cushions into strong packaging slugs.

PadPak Junior: This converter is also suitable for smaller shipping departments. A powerful electric motor provides enough cushioning material. Through using the handle, the comfortable one-handed operation is possible.

Padak CC: PadPak CC is the smallest converter and is particularly suitable for fixing and protecting products in small and medium-sized outer cardboards. Due to its small size, the converter can also be placed on small packaging tables.

PadPak LC: PadPak LC is the fastest PadPak converter. With an output of 1.2 cushion meters per second, it is particularly suitable for the greatest need.

PadPak Guardian: The latest development from the PadPak series. The Guardian converter is compact, quick and easy to handle. The system can be used as an independent unit or next to a work table. PadPak Guardian offers more flexibility for different environments and applications. The paper pads of the PadPak Guardian are perfect for cushioning as well as light and heavy objects. Each pad can be used for corner and edge protection.

The advantages of PadPak briefly explained

The Padpak system offers some profitable advantages: No high costs for individual adapted packagings. PadPak can be used specifically for different products. The packing volume is only arises at the workplace (1 roll makes approx. 2m³). This means that transport and storage costs can be reduced significantly. PadPak consists of 100% paper and can be easily recycled together with the outer box as single-material packaging.

- Less storage space for a large volume

- Natural product, recyclable as single-material packaging with the outer box

- Different systems for a wide variety of requirements

- Can be used flexibly for all types of products

- Reusable

- As a rental system without high acquisition costs

- Trial installation of the machine at your site is possible

- Storage space savings: Compared to many other filling and cushioning materials, the PadPak develops its volume only at the working place. In many cases, this can lead to enormous savings in storage space

- Natural product:PadPak is made from 100% natural materials. This is also an advantage for the end customer, as the padding material can be easily recycled together with the outer box

- Large variety of products: the system is available in different versions for a wide variety of requirements

- More than just a cushion: in addition to excellent cushioning properties, PadPak fixes your product in the outer box

- Reusable: the paper can easily be reused

- No high acquisition costs:The paper cushion system is only a rental system. Therefore, there are no high investment costs for you

- Setting up for testing: PadPak might be the right system for your company? Test the systems without any risk. An experienced packaging specialist will show you the system on site

Your steps to the PadPak system

Whether PadPak is your solution, we should clarify in a personal appointment. First you only need a little time for an appointment with our packaging specialists, who will assess your work environment and gives you individually advice in order to find the best possible packaging solution for you. Anyway: We will be happy to provide you with the PadPak system for a free testing. During the testing phase, you only pay for the packaging material, which you use.

Frequently asked questions to the paper cushioning system

Is it also possible to buy the PadPak machine?

All PadPak machines are only for rent. It is not allowed to buy or to sell them.

Can the PadPak system also be used when there is little space?

Due to the large number of different models, the system can also be placed if there is little space. The PadPak CC is here fore for example an ideal solution. Also the integration of the system into an existing packaging environment is for example possible as the PadPak senior system can directly be used at the table.

Is there any particularly environmentally friendly paper?

For the PadPak senior system we offer a so-called Greenline paper. Due to the high proportion of regulation, this type of paper is not only particularly environmentally friendly, but also the cheapest option.

What types of paper and qualities are there for the paper cushioning system?

Depending on your needs and requirements, you can choose between a 1-. 2- and 3-ply paper in different grammages, which can be selected.

Which packaging materials can be replaced through PadPak?

In general, most filling and cushioning materials can be replaced with the PadPak system, especially packaging chips or air cushion foil.

What is PadPak used for?

PadPak is a system which was developed for the padding of packaged goods on the way of transport. If a product requires particularly high-quality protection during the transport, PadPak is the right choice. However, if cavities should rather be covered, it is better to use a FillPak system.

What happens, if a PadPak machine doesn´t work during the rental period?

If there is a failure or a disruption off the system, our customers receive a qualified support. If the problem can ´t be managed be by phone, a service technician will visit you on site, to take care on the problem. If the system does not work despite all efforts, the machine will be replaced.